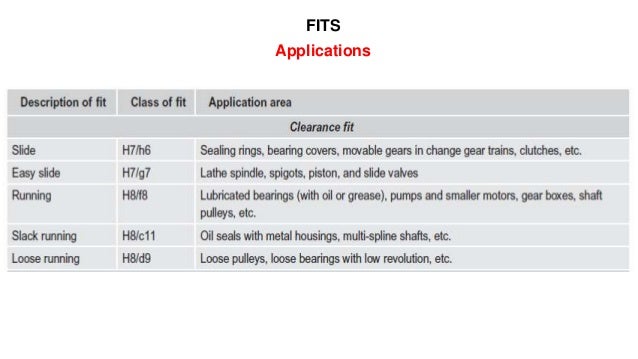

Clearance Fit Application

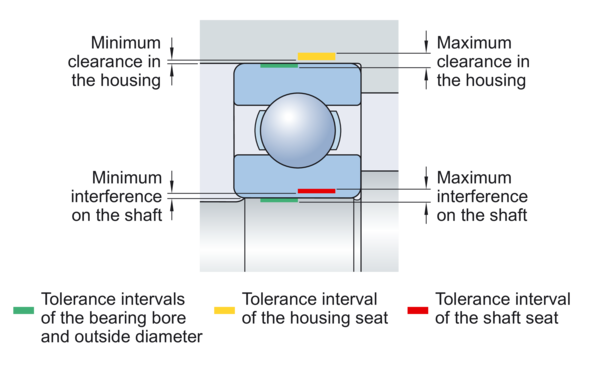

Depending on the amount of interference parts may be joined using a tap from a hammer or pressed together using a hydraulic ram.

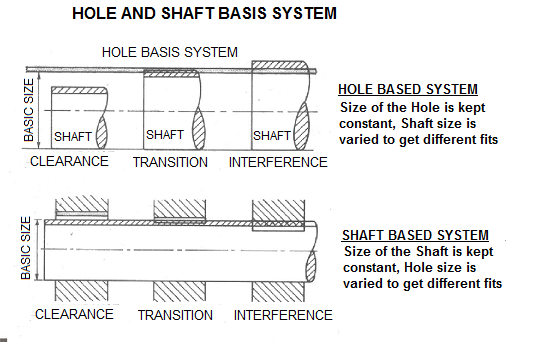

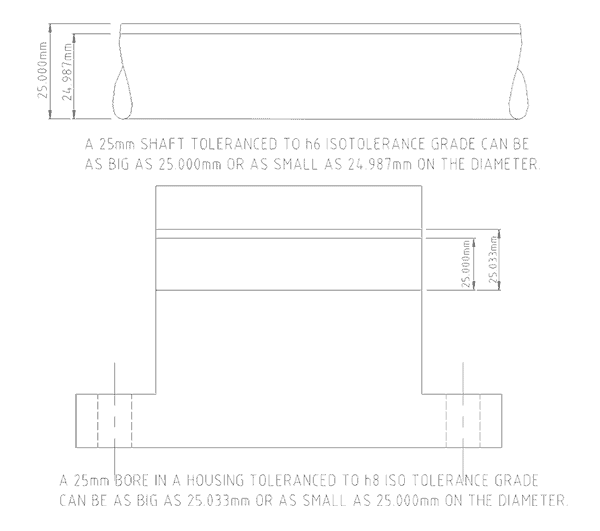

Clearance fit application. In engineering terms the fit is the clearance between two mating parts and the size of this clearance determines whether the parts can at one end of the spectrum move or rotate independently from each other or at the other end are temporarily or permanently joined. Clearance fit means that the two parts in question fit together easily slip together. To find the exact tolerances for each fit with respect to shaft or hole diameter please refer to any data handbook. The first principle to grasp is the fit designation of the shaft hole joint.

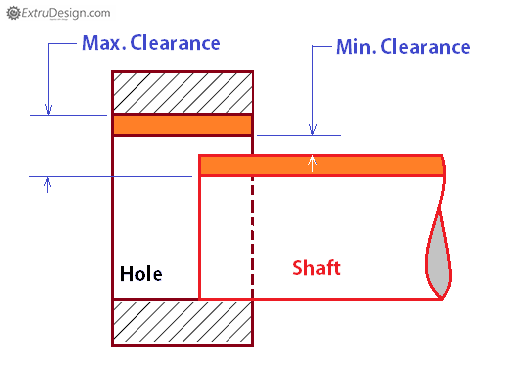

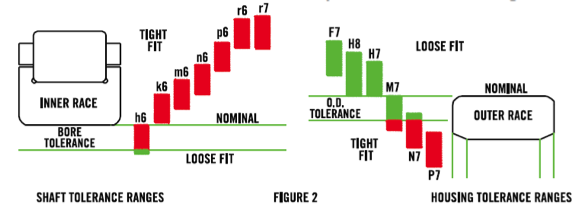

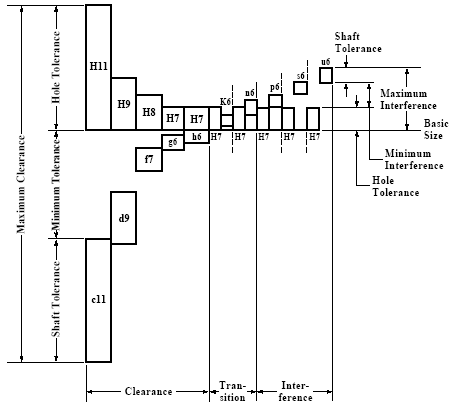

A fit type where clearance or interference can exist between assembled parts depending on tolerance conditions. Here are some guidelines for selecting proper fits for your application. In the clearance fit the largest permitted shaft diameter is smaller than the diameter of the smallest hole. A clearance fit minimum clearance 0 1 maximum clearance 0 2 interference fit bushing mounted in steel plate clearance fit shaft rotating in bushing transition fit gear held in shaft fig.

Loose running fit for wide commercial tolerances or allowances on external members. Gd t is used to define how a part feature relates the other part features in the same part or in a mating part. Gd t a means of dimensioning and tolerancing a part with respect to relationship and function of that part. The fit designation ranges from clearance fits to interference fits.

A clearance fit has positive allowance i e. In mechanical engineering mating of two components is to be determined based on the function of the two components clearance fit interference fit transition fit are the 3 different types of fits. Engineering fits are generally used as part of geometric dimensioning and tolerancing when a part or assembly is designed. The various parameters that can be included are maximum interference minimum interference maximum.

There is minimum ve clearance bet. In clearance fit an air space or clearance exists between the two mating parts. Fit is defined as the degree of freedom of tightness between the mating parts in an assembly process it is also defined as the relationship between the hole and the shaft during the assembly is called fit in this article we are going to discuss different types of fits in a detailed way. Types of fits in engineering fit may be defined as the tightness or looseness between the two mating components.

The difference between the size of the hole and the size of the shaft is defined as clearance. Hole basis h11 c11 shaft basis c11 h11. Clearance fit is one in which two assembled parts are always free to move relative to each other in the assembly. 10 3 application of types of fits.

Clearance to interference fits.