Interference Fit Equations

The interference should be corrected for the effect of surface roughness.

Interference fit equations. This data then can be used to optimize the design of the hub shaft or can be used to find the force to engage and disengage these parts or can be used to find. Note that several errors in the source material have been corrected. An interference fit also known as a press fit or friction fit is a form of fastening between two tight fitting mating parts that produces a joint which is held together by friction after the parts are pushed together. This post is taken from our free textbook analysis and design of composite metallic flight vehicle structures and defines a method for calculating the stresses due to an interference fit bushing.

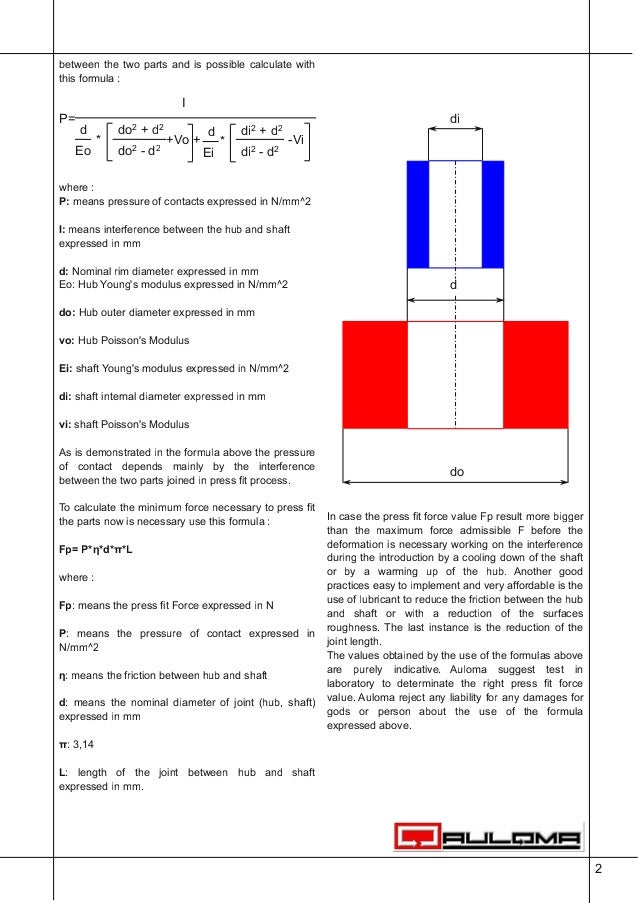

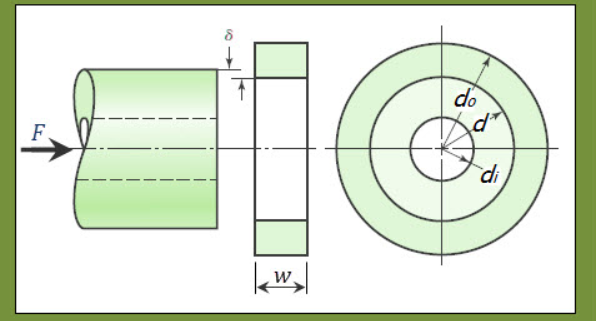

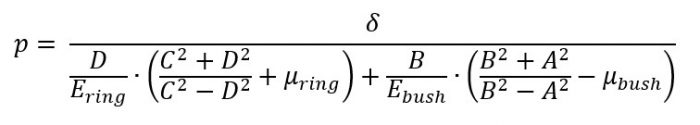

The calculation designs a fit according to the corresponding standards such as iso ansi jis and others. This calculator uses following formula to find the pressure generated with the designed connection. Depending on the amount of interference parts may be joined using a tap from a hammer or pressed together using a hydraulic ram. R d r rα t where r is the interface radius α is the coefficient of thermal expansion t is the temperature change to select an amount of interference see ansi asme tables for class fn1 light to fn5 heavy drive fits.

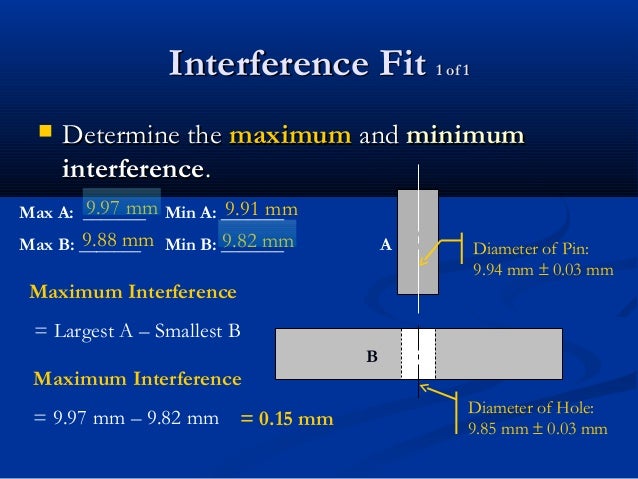

Pressed into a ring which has and od of 200mm. Example calculation of torque transmitted by an interference fit consider a steel shaft 100mm dia. The stresses should be smaller than the elastic limit rp0 2 of the elements. The interference 0 1mm the assumed coefficient of friction μ 0 15.

The standard fit cannot exceed limits for maximum and minimum interference. The maximum and minimum interference. The hub and shaft are both steel with e 210 10 9 n m 2. Differential radial interference due to poisson s effect of axial force u poisson.

An interference fit also known as a press fit or friction fit is a fastening between two parts which is achieved by friction after the parts are pushed together rather than by any other means of fastening. Cylinder pin bolt press fit equations and calculator. Interference and transition fits can be used effectively connect machine elements. The minimum interference from both inequalities is selected as the maximum interference.

The method in this section is referenced to affdl tr 69 42 1986 section 9 16. Critical components that must not sustain. Poissens ratio υ 0 3. Fit is defined as the degree of freedom of tightness between the mating parts in an assembly process it is also defined as the relationship between the hole and the shaft during the assembly is called fit in this article we are going to discuss different types of fits in a detailed way.

Formulas for interference press shrink fit calculations interference fit formulas for press fit and shrink fit calculations. The length of the hole is 50mm. The calculator is based on elastic deformation lame s equation i e.