Press Fit Tolerance Chart Pdf

M7 k7 possible axial.

Press fit tolerance chart pdf. Tolerances for housing bores axial displacement of outer ring remarks p7 n7 impossible generally impossible if axial displacement of the outer ring is not required. This type of tolerance can be usable where any special requirements for accuracy in not essential but good for wide temperature variation heavy journal pressures and high running speeds. When high accuracy is required very strict tolerances should be used for fitting. The schematic representation of the fit is also drawn.

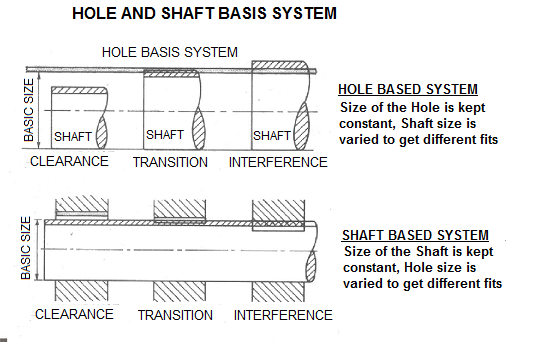

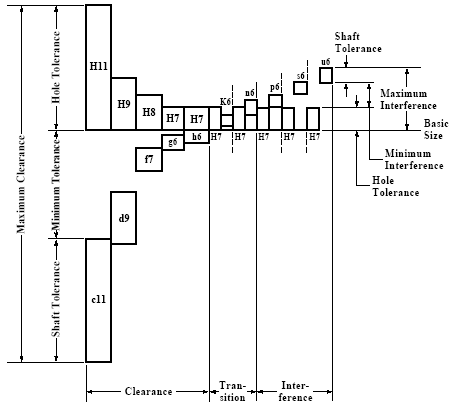

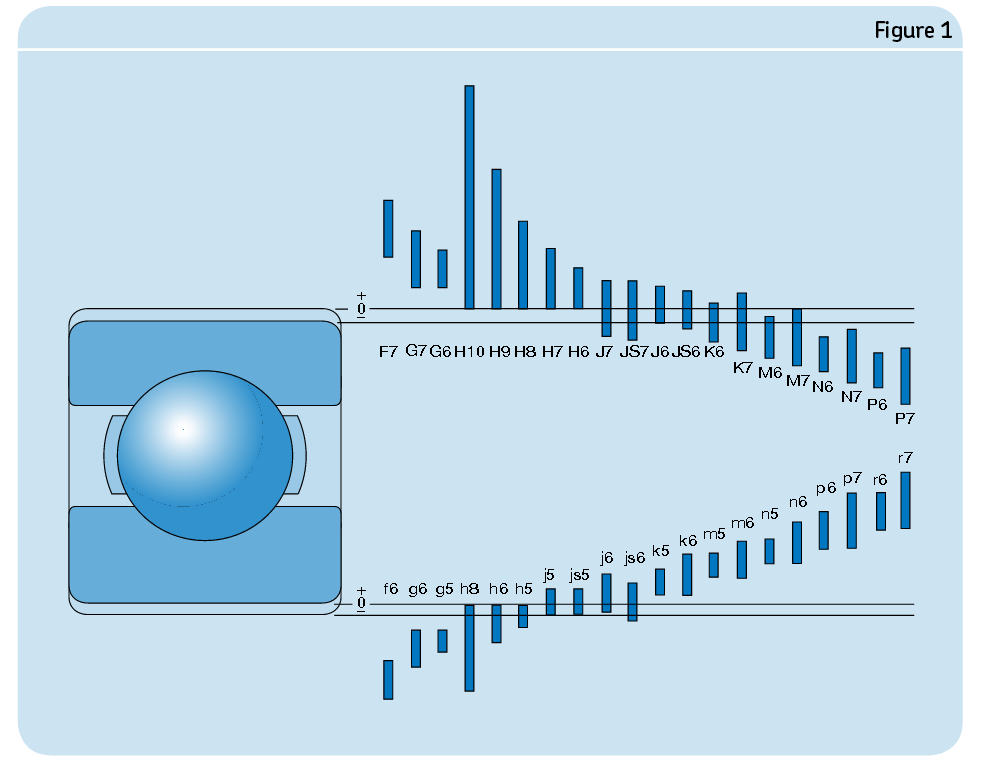

Evaluate limits and fits for an assembly pair 6 h7 g6 mm solution. The usage of these tolerances is advised for economic reasons. The following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide machining tolerances. Preferred fits and tolerances charts iso ansi metric standards preferred fits and tolerance table for hole and shaft basis systems which are given in iso 286 1 2010 and ansi b4 2 1978 standards.

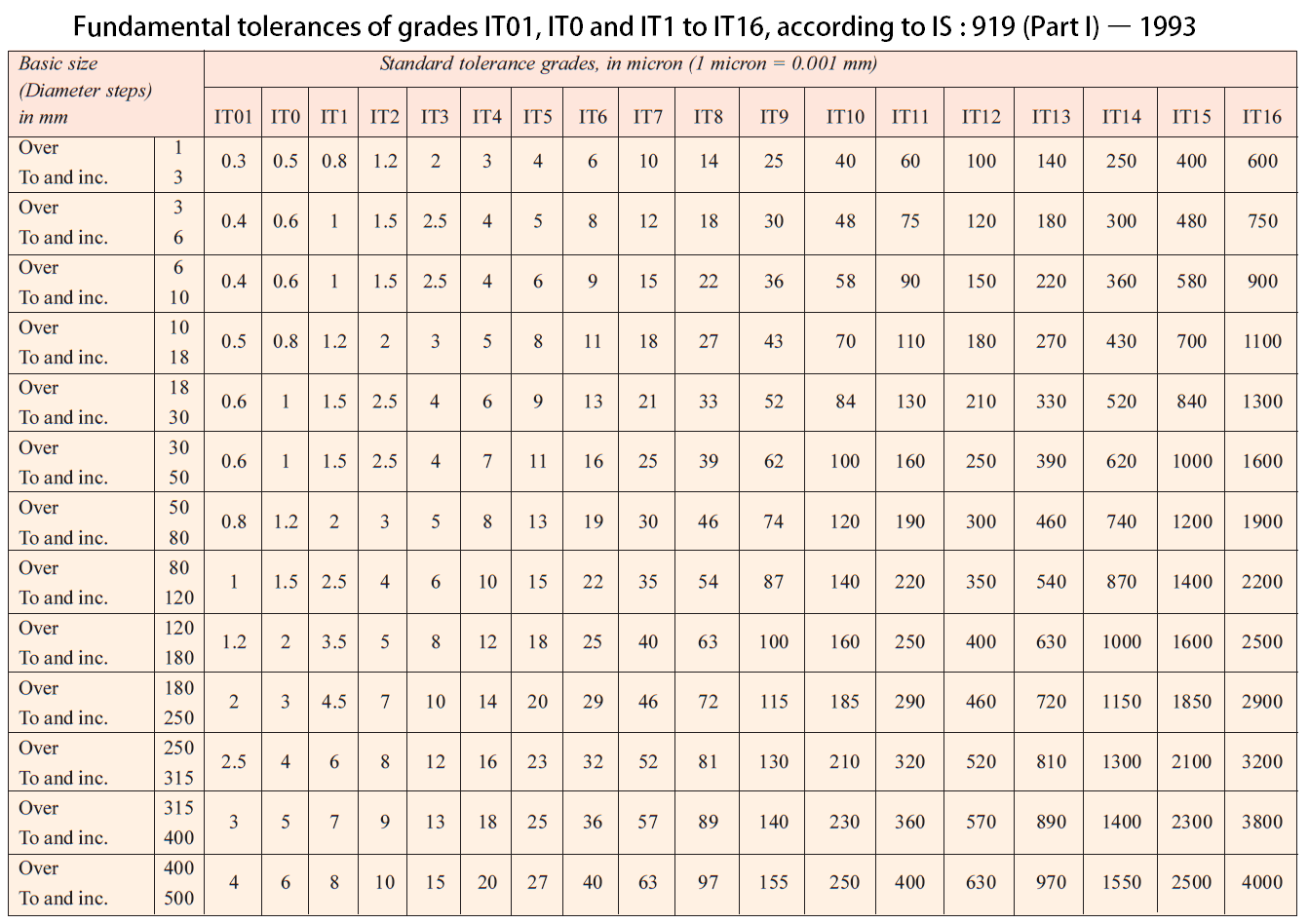

The fundamental tolerance unit is 0 7327 μm tolerance for hole h7 tolerance 16i 12 μm the fundamental deviation h hole zero tolerance for g6 shaft tolerance 10i 8 μm. This standard defines preferred limits and fits for press fits applications of non threaded cylindrical features preferred tolerances limits fits calculator rc lts this calculator will determine the preferred size and limit tolerances for running or sliding to interference locational fits per ansi b 4 1. H9 d9 d9 h9 h9 c9 h9. H9 e9 h8 e8 h7 e7 e9 h9 e8 h8 e8 h7 running fits with greater clearances without any special requirements for fit accuracy main fits of machine tools.

The size 6 mm lies in the diameter step of 3 6. Some of the applications. The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection. Multiple fits of shafts of production and piston machines parts rotating very rarely or only swinging.

Multiple fits of shafts of production and piston machines parts rotating very rarely or only swinging. For heavy loads interference fit tight than k is used. The size ranges given are for typical size ranges utilized within industry. Mechanical tolerance standards charts geometric boundaries ii gd t reference book.

In practice compound tolerance should be avoided as far as possible. Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards. For example tolerance for the dimension r is determined by the combined effects of tolerance on 40 mm dimension on 60º and on 20 mm dimension.