Press Fit Tolerance Metric

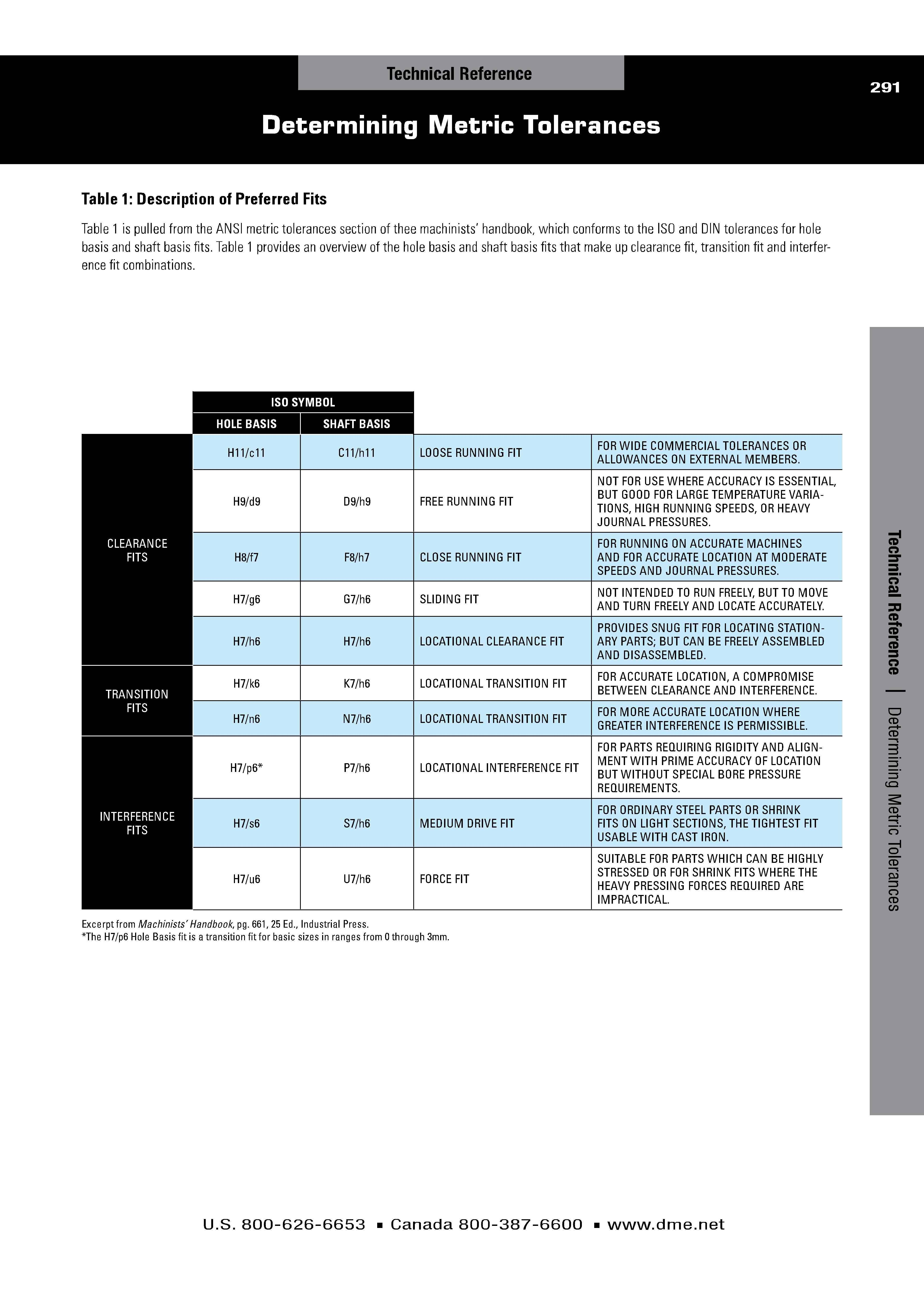

Loose running fit for wide commercial tolerances or allowances on external members.

Press fit tolerance metric. Press fit tolerance metric mm bore diameter. Preferred mechanical tolerances metric iso 286. Hole based fits should be preferred. 25 h11 or 25 c11 a fit is defined by the basic size followed by the tolerance of each component.

The usage of these tolerances is advised for economic reasons. Up to 50 0 50 1 to 80 0 80 1 to 120 0 120 1 to 180 0 180 1 to 300 0 300 1 to 500 0 0 10 0 20. They re offered in a wide variety of configurations. The schematic representation of the fit is also drawn.

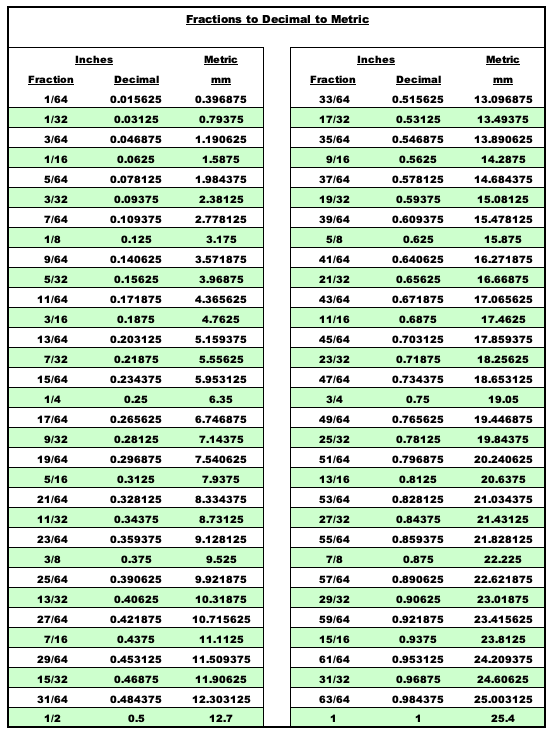

Standard i d s o d s and lengths are millimeters mm. Press fit pressure calculator optimize your interference. A feature tolerance is defined by the basic size followed by the tolerance designation. The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection.

The standards include iso 286 ansi b4 2 and din 7172. Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards. 25 h11 c11 or separated with a dash ex. Press fit tolerance metric fitness and workout.

Electro mechanical design hand splash page. With the press fit if your hole is 0 0007 inches too big you won t have any interference at all so tolerances become extremely important. Locating and fixturing pins selection ering360. Type pm metric press fit headless bushings are the most popluar and least expensive.

Slip fit tolerances and geometry fictiv hardware. However with a bolt you can drill a hole with a diameter tolerance of 0 020 inches. Mechanical tolerance chart data. Which takes us to our next area of discussion.

25 h11 c11 fits are either based on the hole feature or the shaft feature. This standard defines preferred limits and fits for press fits applications of non threaded cylindrical features preferred tolerances limits fits calculator rc lts this calculator will determine the preferred size and limit tolerances for running or sliding to interference locational fits per ansi b 4 1. There are actual standards that define exactly what tolerances need to be to achieve various kinds of fits such as sliding fit press fit force fit free running fit and so on. Preferred fits and tolerances charts iso ansi metric standards preferred fits and tolerance table for hole and shaft basis systems which are given in iso 286 1 2010 and ansi b4 2 1978 standards.